The eccentric screw pumps are positive-displacement self-priming pumps with a single rotating axis. Steel rotor and rubber stator are the main elements for pumping. Their strong point is to move the product delicately and constantly. Suitable for handling low-viscosity products, high-viscosity products and also products with solid particles in suspension, without compromising the proper operation.

Capacity: up to 130 m3/h

Pressure: up to 24 bar

Applications:

- Food processing industries.

- Beverage industries.

- Chemical, printing and extractive & textile industries.

- Cosmetic and pharmaceutical industry.

- Tile building and related industries.

- Water purifying and conditioning plants.

- Oenological industry.

Products Ranges:

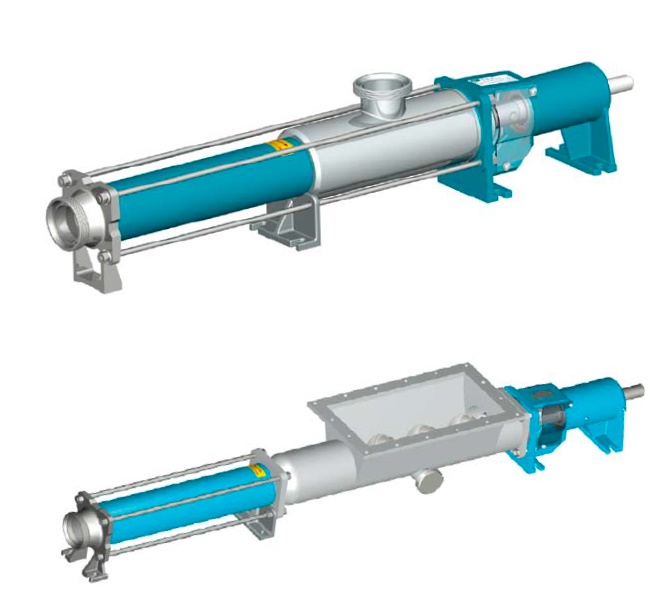

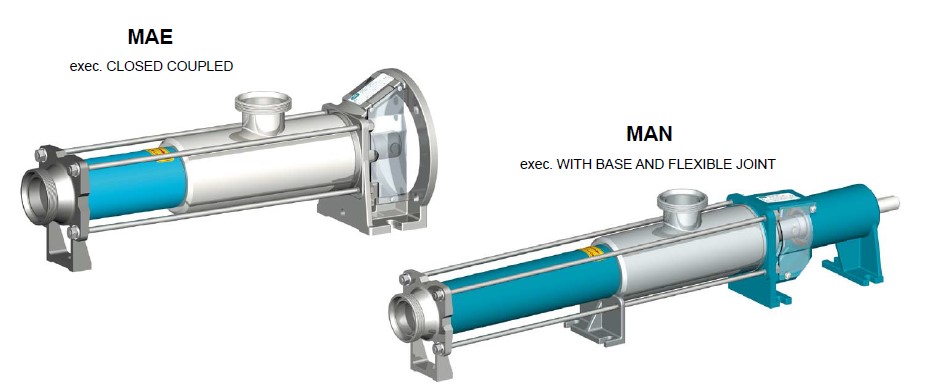

MA Series:

Food series pumps with wide exhaust chamber designed for sanitary use. The metallic parts in contact with the product are in satin/polished stainless steel.

MAE: The enbloc type pump is directly coupled with the motorization reducing to the minimum size and costs.

MAN: The special telescopic assembly with base & flexible joint allows a quick inspection of the pump without affecting the supporting part and motorization, and facilitating the cleaning and maintenance.

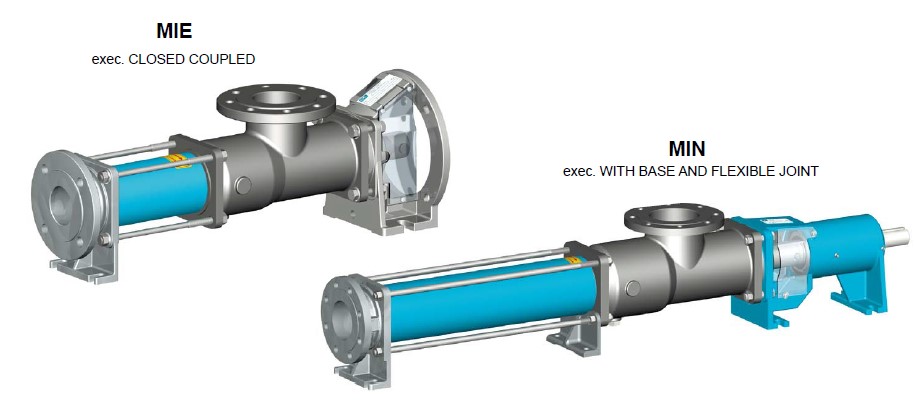

MI Series

Industrial sturdy pumps with flanged inlets suitable for heavy duty uses. Exhaust chamber and delivery inlet can be in stainless steel or in cast iron. The rotating parts are exclusively in stainless steel.

MIE: The enbloc type pump is directly coupled with the motorization reducing to the minimum size and costs.

MIN: The special telescopic assembly with base & flexible joint allows a quick inspection of the pump without affecting the supporting part and motorization, and facilitating the cleaning and maintenance.

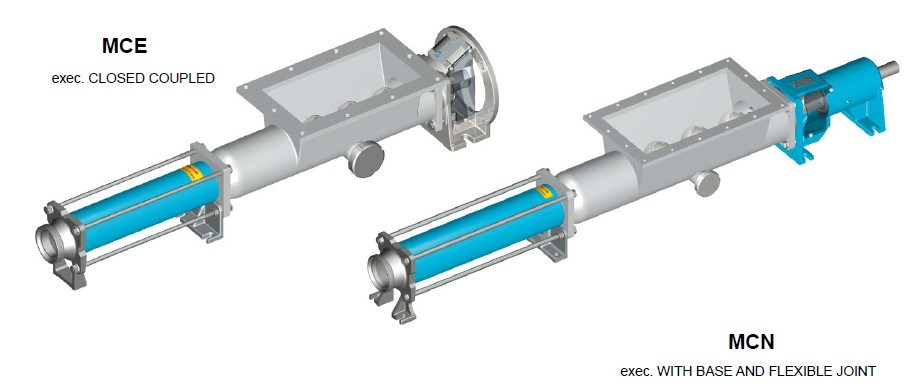

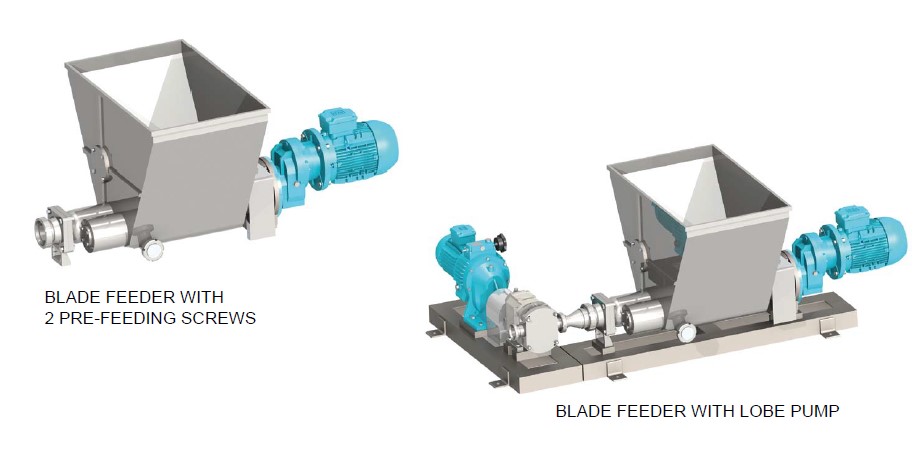

MC Series

Pump with coaxial hopper provided with pre-feeding scroll suitable for handling viscous products.

MCE: The enbloc type pump is directly coupled with the motorization reducing to the minimum size and costs.

MCN: The special telescopic assembly with base & flexible joint allows a quick inspection of the pump without affecting the supporting part and motorization, and facilitating the cleaning and maintenance.

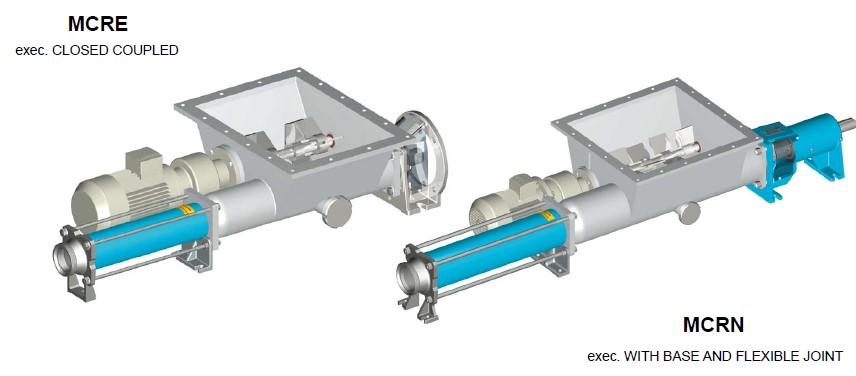

MCR Series

Pump with hopper provided with pre-feeding scroll and bridge breaker, suitable for products by lump that form a bridge on the scroll. A closing cover allows using the pump also for the special MAE and MAN series

MCRE: The enbloc type pump is directly coupled with the motorization reducing to the minimum size and costs.

MCRN: The special telescopic assembly with base & flexible joint allows a quick inspection of the pump without affecting the supporting part and motorization, and facilitating the cleaning and maintenance.

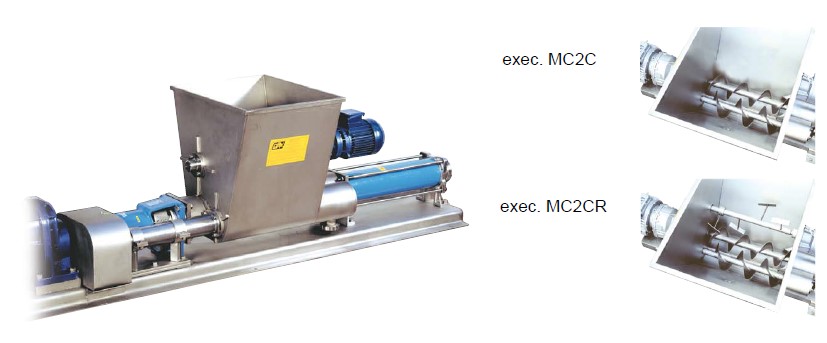

MC2C – MC2CR Series

Version with hopper and double synchronized pre-feeding screw, with vane crusher operated by a reduction unit. The two pre-feeding screws pull the product to feed the pump stator. The vane crusher blades push the product towards the bottom of the hopper thus feeding the two pre-feeding screws and preventing product stagnation. They are ideal for very viscous products that do not flow easily, such as dough, minced products and products in blocks. Suitable for products in blocks for which a crushing is required to feed the pump screw.

MAV Series – Vertical Execution

The MAV series progressive cavity pumps are designed for vertical operation with the inlet immersed in the product. The operating characteristics and construction materials of these pumps enable them to be used with many different fluids, from low to high viscosity, including many abrasive and corrosive media. An added benefit is the ability to handle fluids containing fibers or solid materials in suspension.

Progressive cavity pump with crushing blades.

For crushing your products containing soft or fibrous components (fruit or vegetables. By using crushing blades mounted on the rotor with a disc having holes of different sizes, the consistency of the mashed product can vary. The great advantage of this device is to avoid the need for macerating equipment after the pump.